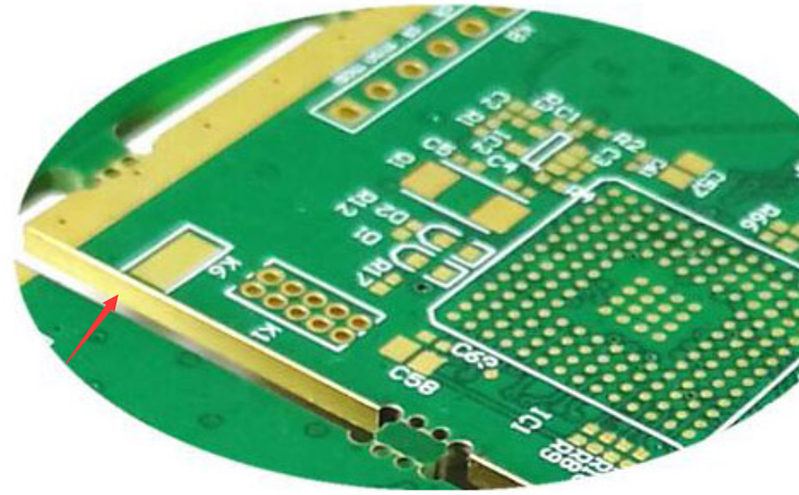

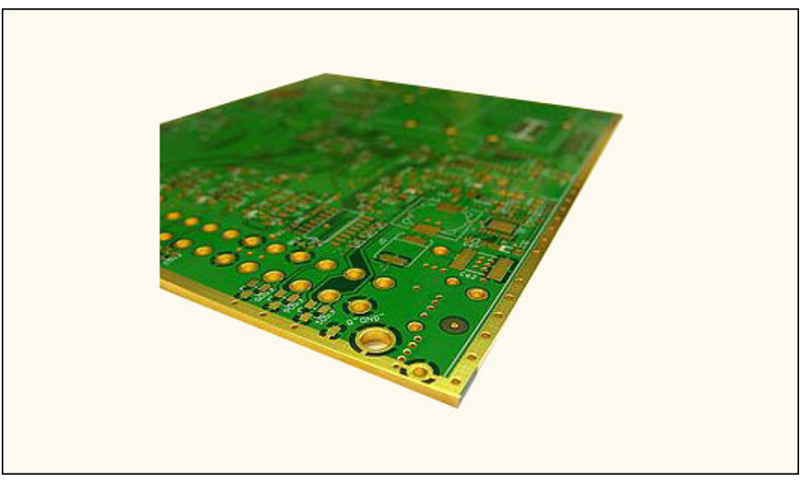

This is a special product request for edge plating. The edge plating refers to the copper plating that runs from the top to the bottom surfaces of the circuit board and extends to at least one of the perimeter edges.

For standard PCB, normally don’t accept copper on the board edge to avoid short when assembly, but edge plating PCB has a special function requirement.

So PCB edge castellation makes sure there is a strong connection with the circuit board and limits the chance of equipment failures, particularly while controlling the protections for sub-motherboards and small form factor boards.

Pls contact us at [email protected] for your PCB/FPC/PCBA/FPCA/STENCIL/ASSEMBLY service.

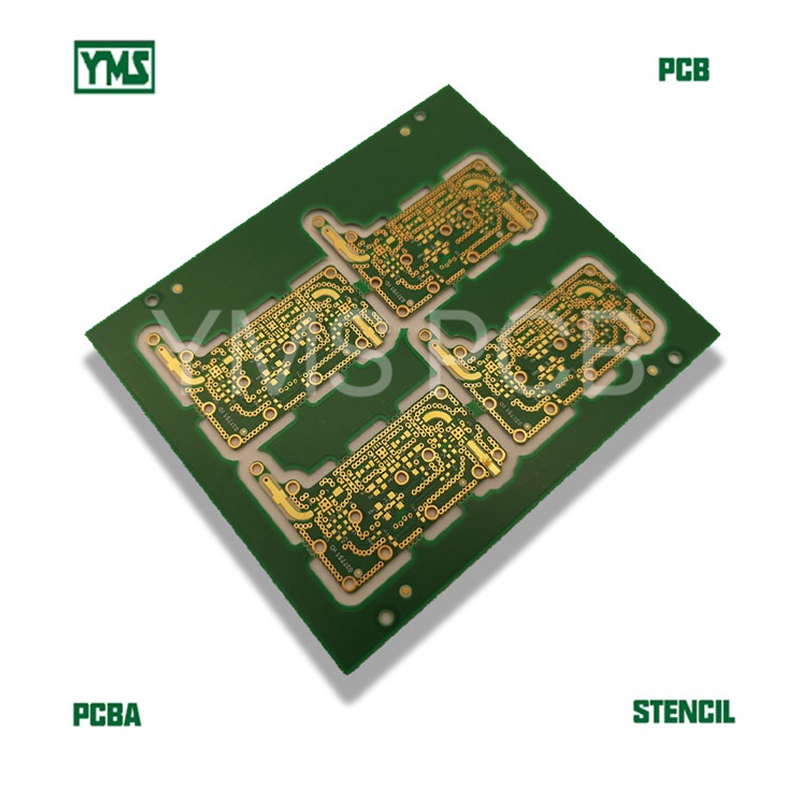

Layers: 6 layers

Board Thickness: 2.2mm+/-10%

PCB Size: 165mm x 110mm

Copper weight: 1 OZ for the outer layer and 1 OZ for the inner layer

Material: FR-4 + ROGERS (L1-L2/L3-4 is ROGERS material, L2-L3 is standard FR-4 material)

Min Holes:0.2mm (8mil)

Minimum Line Width/Clearance:4mil/4mil

Surface Treatment: ENIG + edge plating

Applications: Edge plating PCB has been widely used in many industries, particularly in applications that need better support for connections

Solder mask color: green

Silkscreen color: white

YMS PCB fabricates the edge plating circuit boards with specialized equipment and training

personnel for the process although edge plating on printed circuit boards is a simple addition in

many cases.

In addition, designers need to make sure that there is a band of copper on both edges of the top

and bottom side because the plating will connect to the copper bands.

Pls contact us at [email protected] for your PCB/FPC/PCBA/FPCA/STENCIL/ASSEMBLY service.

Eddi Yan

0755-26484826

0755-26484827

ECheng Industrial Park,Tongqiao Town,Zhongkai High-Tech Zone,Huizhou,Guangdong,China

Room 402-405, Fu Lin Building, Qiao Tou, Fu Yong, Baoan,Shenzhen,Guangdong,China